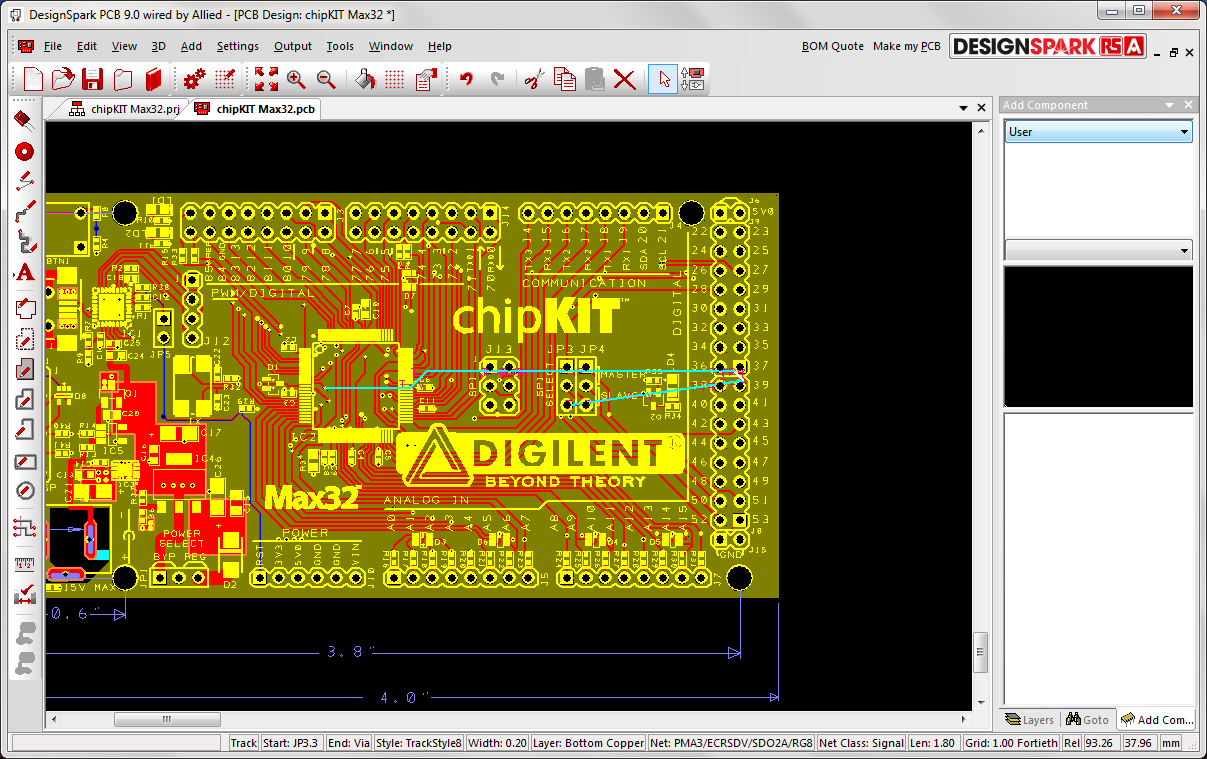

It works to achieve netlist synchronisation between related schematic sheets and PCB designs. After translating schematic to PCB, if any changes are made in schematic the same can be transferred to PCB layout using Forward Design Changes option. 5: Manufacturing plotįorward Design Change and Back Annotations. And by combining the power of an auto-router with your experience in PCB layout, the resulting design can beat even the most labour-intensive manual layout results in terms of manufacturability, cost and even aesthetics. Using an auto-router to route even part of your PCB will give you a significant saving in time. This helps you identify and correct the error.Īuto-routing.DesignSpark PCB supports complete auto-routing, partial auto-routing and manual routing.

When the Design Rule Check is run and errors found, textual error markers get added to the design with the appropriate code for that rule violation.

Then there are other design rules related to nets, vias, drills and lot many things. While designing a PCB, designers should keep in mind basic points like minimum track width, minimum annular ring, track-track clearance, track-pad clearance and pad-track clearance.

0 kommentar(er)

0 kommentar(er)